Posts Tagged ‘concrete patio’

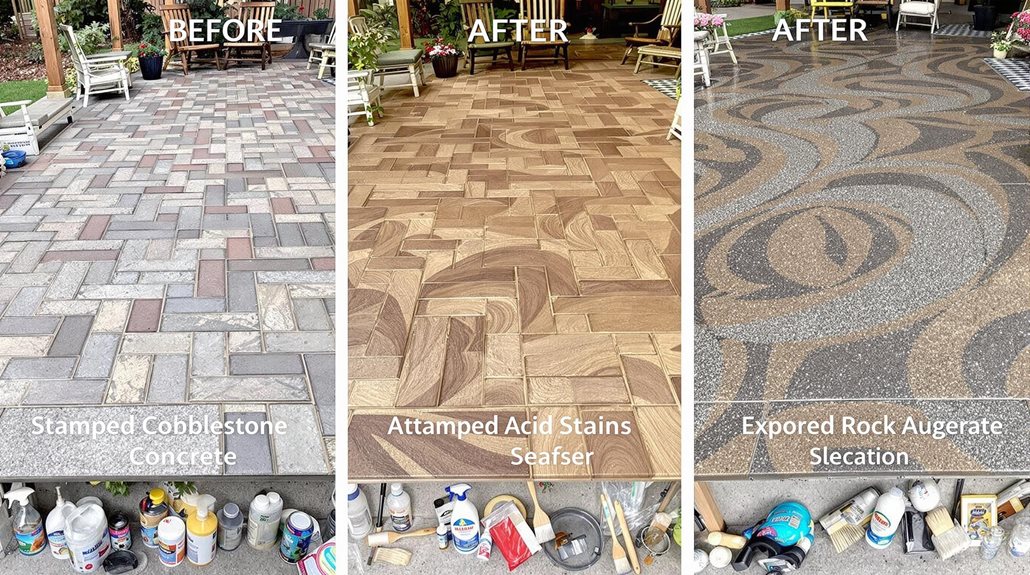

Concrete Patio Material Choices Stamped, Stained, Exposed Aggregate

Modern concrete patios offer three primary decorative finishes: stamped patterns that replicate natural stone or brick through textured molds, acid staining that creates variegated earth-tone colors through chemical reactions, and exposed aggregate that reveals decorative stones embedded within the surface. Each option carries distinct maintenance requirements and costs, with stamped concrete ranging $15-20 per square foot, staining at $8-12, and exposed aggregate at $10-15. Understanding the unique characteristics of each finish enables best selection based on aesthetic preferences and regional climate conditions.

Expert Highlights

- Stamped concrete replicates natural materials like stone and brick, requiring coordinated mixing and timing for successful pattern application.

- Acid staining creates unique earth-toned colors through chemical reactions, offering diverse color intensities for sophisticated finishes.

- Exposed aggregate reveals decorative stones like river rock or granite chips through pressure washing and chemical retarders.

- Standard gray concrete costs $6-8 per square foot, while decorative finishes can reach $15-30 per square foot.

- All decorative concrete options require specific maintenance schedules, including annual sealing, pressure washing, and regular cleaning.

Understanding Basic Concrete Patio Options

Homeowners exploring concrete patio options must first understand the fundamental choices available regarding basic materials, finishes, and construction methods.

Traditional concrete patios utilize Portland cement mixed with aggregates and water, creating a durable surface that can last decades when properly installed and maintained.

Traditional concrete patios blend Portland cement, aggregates, and water to create long-lasting outdoor surfaces that endure through proper installation and maintenance.

The basic installation process involves preparing a stable subgrade, installing proper drainage and reinforcement, then pouring and finishing the concrete mixture.

While standard gray concrete remains popular due to its affordability and versatility, modern techniques allow for enhanced aesthetic appeal through various finishing methods.

Concrete thickness typically ranges from 4 to 6 inches for residential patios, with thicker slabs required for areas supporting heavy loads or experiencing freeze-thaw cycles.

The concrete mix design must achieve a minimum compressive strength of 3,500 PSI for peak durability and crack resistance.

Working with licensed contractors ensures reliable installation and proper construction techniques from start to finish.

The Art and Appeal of Stamped Concrete

Stamped concrete transforms ordinary concrete patios into artistic surfaces that can replicate the look of natural stone, brick, slate, or even wood grain through specialized patterns and texturing techniques.

The installation process combines colored concrete placement, carefully-timed surface pressing with specialized rubber mats or forms, and skilled finishing work to create three-dimensional impressions that mimic high-end materials.

Professional contractors must coordinate multiple steps precisely, including proper concrete mixing ratios, color hardener application, release agent usage, and stamping timing to achieve ideal pattern depth and authentic-looking textures.

With proper maintenance practices, stamped concrete surfaces can maintain their beauty and structural integrity for over 25 years.

Stamped Pattern Design Options

When exploring the artistic possibilities of concrete patios, stamped patterns emerge as one of the most versatile and aesthetically pleasing design options available to modern construction. The selection of patterns ranges from natural stone textures, including slate, flagstone, and cobblestone, to geometric designs and repeating motifs that complement various architectural styles.

Professional contractors can implement intricate designs using specialized tools and forms, creating authentic-looking textures that mimic high-end materials at a fraction of the cost. Popular options include ashlar cut stone, which features a classic rectangular pattern, and seamless texture skins that replicate weathered wood or natural rock formations.

The depth and complexity of these patterns can be further enhanced through strategic coloring techniques, including integral pigments, color hardeners, and release agents, which add dimension and realism to the finished surface.

Installation and Finishing Process

The intricate process of concrete patio installation begins with thorough site preparation, including proper grading, compaction of the base material, and installation of forms to contain the wet concrete mixture.

Reinforcement materials, such as steel mesh or fiber additives, are positioned to prevent cracking and guarantee structural integrity.

Once the concrete is poured and leveled, contractors apply a release agent to prevent the stamping tools from adhering to the surface.

The concrete must reach the ideal consistency before skilled technicians carefully press specialized rubber mats or stamps into the semi-hardened surface to create the desired pattern and texture.

Final finishing steps include cleaning excess release agent, applying concrete sealers for protection, and allowing proper curing time, typically 24-48 hours for foot traffic and 7-10 days for vehicle traffic.

Color Variations Through Acid Staining

Transforming ordinary concrete into rich, variegated surfaces becomes possible through acid staining, a chemical reaction process that permanently alters the concrete's appearance.

The stains, typically containing metallic salts suspended in an acidic water-based solution, penetrate the concrete surface and react with calcium hydroxide, creating unique earth-toned colors.

Chemical artistry unfolds as metallic salts merge with concrete's calcium hydroxide, transforming gray surfaces into rich, earthen masterpieces.

The resulting patterns emerge in warm browns, terra cottas, and subtle blues or greens, depending on the specific chemical compounds used in the staining process. Multiple applications can create layered effects, while varying the dilution ratios affects color intensity. Environmental factors, such as concrete age and surface conditions, influence the final outcome.

Professional applicators often combine different staining techniques, including spray methods and brush applications, to achieve sophisticated marbling effects that mimic natural stone or leather textures.

With expert craftsmanship from skilled professionals, these decorative finishes can transform both residential and commercial concrete installations into stunning architectural features.

Exposed Aggregate: Natural Beauty Revealed

Exposed aggregate installation involves multiple steps, beginning with placing and screeding the concrete mix, followed by washing away the surface mortar to reveal decorative stones beneath.

The process allows contractors to create varied patterns through stone selection and placement techniques, incorporating natural river rock, granite chips, or colored glass in sizes ranging from 1/8 to 3/4 inch.

Designers can achieve striking visual effects by combining different aggregate materials and colors, from earth-toned pebbles that create a naturalistic appearance to vibrant glass chips that produce a modern, architectural statement.

As a certified team member of Legacy General Services, our experts ensure pristine installation and superior quality control throughout the exposed aggregate process.

Installation Steps and Methods

Creating an exposed aggregate patio requires a systematic, multi-step approach that begins well before the concrete is poured.

Initial site preparation involves grading, compacting the soil, and installing proper forms and reinforcement mesh to guarantee structural integrity.

Once the concrete mix is poured to the desired thickness, contractors must wait for the precise moment when the surface begins to set.

At this critical stage, a chemical retarder is applied to delay surface curing while the underlying concrete hardens.

After approximately 24 hours, workers carefully pressure wash the surface to expose the decorative aggregate.

The final steps include allowing the concrete to cure completely for 7-10 days, applying a protective sealer to enhance the aggregate's appearance, and installing control joints to prevent random cracking.

This methodical process guarantees a durable, aesthetically pleasing result.

Patterns and Color Options

Through careful selection of aggregates and matrix colors, exposed aggregate patios offer an extensive range of aesthetic possibilities that blend natural sophistication with practical durability.

Homeowners can choose from river rock, granite chips, or even recycled glass aggregates in various sizes and hues, creating distinctive visual textures that complement surrounding landscapes.

The matrix concrete itself can be tinted using integral color admixtures or surface-applied stains in earth tones, warm grays, or bold terracotta shades.

When combined with different exposure depths and seeding patterns, these options produce unique surface effects ranging from subtle to dramatic.

Professional contractors often create custom aggregate blends, mixing different sizes and colors of stone to achieve specific design objectives while maintaining ideal surface consistency and structural integrity throughout the installation process.

Maintenance Requirements for Different Finishes

While different concrete patio finishes can greatly enhance outdoor spaces, each type requires specific maintenance protocols to preserve its appearance and structural integrity over time.

Selecting the right concrete patio finish demands commitment to proper maintenance practices to ensure lasting beauty and performance.

The level of maintenance needed varies considerably based on the finish type, environmental conditions, and usage patterns.

- Stamped concrete surfaces need annual sealing and occasional pressure washing to prevent staining and maintain color vibrancy.

- Exposed aggregate finishes require periodic cleaning with specialized cleaners to remove organic debris from between stones.

- Stained concrete demands biannual sealing and prompt spill cleanup to protect the coloring agents.

- Polished concrete surfaces benefit from weekly dust mopping and monthly wet cleaning with pH-neutral cleaners.

- Smooth-troweled finishes need regular sweeping and occasional degreasing to prevent slip hazards.

Regular inspection and prompt repairs of any cracks or damage help maintain long-term durability across all finish types.

With proper care and maintenance, concrete surfaces can provide 30 years of service when professionally installed and maintained according to recommendations.

Cost Comparisons Across Patio Styles

The cost variation between basic and premium concrete patio finishes can be substantial, with plain gray concrete starting at $6-8 per square foot while decorative options often exceed $15-20 per square foot.

Premium finishes, such as stamped patterns, exposed aggregate, or stained concrete, typically command higher prices due to increased labor requirements, specialized tools, and more expensive materials.

Installation complexity also impacts overall costs, as intricate designs requiring multiple colors, detailed patterns, or custom scoring can push prices toward $25-30 per square foot or higher in many markets.

With proper maintenance and professional installation by certified concrete experts, these premium concrete finishes can maintain their beauty and durability for up to 30 years.

Average Costs Per Square

Selecting an appropriate concrete patio style requires careful consideration of material costs, which can vary considerably across different options and finishes. Industry averages indicate significant price variations between basic and premium installations, with regional factors affecting final costs.

- Plain concrete patios typically range from $6 to $12 per square foot

- Colored concrete increases costs to $12 to $18 per square foot

- Stamped patterns elevate pricing to $15 to $25 per square foot

- Exposed aggregate installations average $12 to $20 per square foot

- Custom designs with multiple colors and patterns can exceed $30 per square foot

These price points reflect complete installation costs, including base preparation, reinforcement materials, and finishing work.

Labor typically represents 40-60% of total costs, while material expenses vary based on concrete grade, color additives, and surface treatment complexity.

Premium Vs Basic Options

Comparing premium and basic concrete patio installations reveals considerable cost differentials across various style categories, with luxury options often commanding prices 200-300% higher than standard alternatives.

Premium finishes, such as stamped patterns with multiple colors and sealed surfaces, typically range from $15-25 per square foot, while basic broom-finished concrete averages $6-8 per square foot.

High-end treatments incorporate advanced materials like color hardeners, release agents, and protective sealers, which considerably enhance both aesthetics and durability. These premium installations often feature intricate patterns, seamless texturing, and carefully controlled curing processes that require specialized expertise.

Basic installations, while functional and durable, utilize standard gray concrete with simple finishing techniques, making them an economical choice for budget-conscious property owners who prioritize function over decorative elements.

Weather Resistance and Durability Factors

When constructing a concrete patio that will endure for decades, weather resistance and durability factors play crucial roles in material performance and longevity.

Environmental conditions, including freeze-thaw cycles, UV exposure, and precipitation patterns, considerably impact concrete's structural integrity and appearance over time.

Key factors affecting concrete patio durability include:

- Compressive strength rating, typically 3,000 to 4,000 PSI for residential applications

- Air-entrainment percentage, ideally 5-7% for freeze-thaw resistance

- Water-to-cement ratio, ideally 0.45-0.50 for maximum durability

- Surface sealant type and reapplication schedule

- Proper installation of control joints every 8-12 feet

Professional contractors incorporate these durability considerations during both the design and implementation phases, ensuring the finished patio withstands local climate challenges while maintaining its aesthetic appeal through seasonal changes and years of use.

Installation Methods and Timeline

A successful concrete patio installation requires careful planning, precise execution, and adherence to specific timelines throughout multiple phases of construction.

The process typically begins with site preparation, including grading, compaction, and installation of forms and reinforcement, which takes 1-2 days.

Proper site preparation forms the foundation of any successful concrete project, ensuring stability through careful grading, thorough compaction and strategic reinforcement placement.

The concrete pour represents the most critical phase, requiring coordination of delivery trucks and finishing crews to complete the placement within a 2-4 hour window.

After screeding and floating, contractors must wait for the ideal moment to begin finishing operations, including texturing and edging.

The curing phase demands strict attention to temperature and moisture conditions over 7-28 days.

During this period, the concrete should be kept consistently damp and protected from extreme weather conditions, while bearing no significant weight or traffic.

Design Patterns and Border Options

Modern concrete patios offer homeowners an extensive array of design patterns and decorative border options that transform basic slabs into sophisticated outdoor living spaces.

Common design elements incorporate geometric shapes, natural stone patterns, and distinctive border treatments that define spaces and create visual interest.

Professional contractors can implement numerous artistic patterns through:

- Stamped impressions mimicking brick, slate, or cobblestone textures

- Scored patterns creating clean lines and symmetrical sections

- Stenciled designs featuring intricate medallions or custom motifs

- Exposed aggregate borders providing textural contrast

- Saw-cut patterns forming precise geometric shapes

Border treatments often feature contrasting colors or textures that frame the main patio area, incorporating detailed edge work such as bullnose finishing or rolled edges.

These design elements can complement existing architecture while establishing distinct outdoor zones for various activities.

Selecting the Right Finish for Your Climate

Beyond aesthetic design choices, climate conditions considerably influence the selection of concrete patio finishes, as different surface treatments perform differently under varying weather patterns and environmental stresses.

| Climate Type | Recommended Finish | Key Benefits |

|---|---|---|

| Hot/Arid | Smooth Trowel | Reflects heat, minimizes cracking |

| Wet/Humid | Broom Finish | Enhanced traction, water drainage |

| Freeze/Thaw | Salt Finish | Slip resistance, ice management |

For regions experiencing significant temperature fluctuations, penetrating sealers provide superior protection against moisture infiltration and freeze-thaw damage, while maintaining the concrete's ability to breathe. Coastal environments benefit from densifiers and water-repellent treatments that protect against salt exposure and humidity, extending the patio's longevity through enhanced chemical resistance and reduced efflorescence.

Frequently Asked Questions

Can Concrete Patios Be Installed Over Existing Concrete Slabs?

Most homeowners can successfully overlay new concrete onto existing slabs if the base is structurally sound, properly prepared, and has adequate drainage. Professional installation guarantees the best results.

How Long Should I Wait Before Placing Furniture on New Concrete?

Most homeowners should wait at least 24-48 hours before placing light furniture on new concrete, but heavy items require a full 7-10 days for proper curing and maximum strength.

What Causes White Spots or Efflorescence on Concrete Patios?

Efflorescence occurs when water dissolves salt deposits within concrete and carries them to the surface. As moisture evaporates, these salts remain behind, creating white, chalky spots on concrete surfaces.

Can Plants or Tree Roots Damage My Concrete Patio Over Time?

Growing tree roots and aggressive plant systems can gradually crack and lift concrete patios by exerting pressure from below, causing structural damage and uneven surfaces over several years.

Is It Possible to Repair Cracks Without Replacing the Entire Patio?

Small to medium concrete cracks can be repaired using epoxy fillers, patching compounds, or concrete sealants. Many homeowners successfully fix these issues without needing complete patio replacement.

Expert Final Thougts

When choosing a concrete patio finish, homeowners must carefully weigh aesthetic preferences against practical considerations like maintenance needs, climate compatibility, and installation costs. While stamped concrete offers design versatility, acid staining provides rich color variations, and exposed aggregate delivers natural texture, each option presents distinct advantages and challenges. Through thoughtful evaluation of these factors, along with proper installation and maintenance, any of these finishes can provide decades of outdoor enjoyment and value.

Concrete Patio Installation Process Site Preparation, Curing Time

Installing a concrete patio requires thorough site assessment, proper drainage evaluation, and soil testing for load capacity. The process involves excavating 4-6 inches deep, installing a 4-inch compacted gravel base, and building sturdy forms with correct slope for drainage. Once concrete is poured and finished, the critical curing period spans 7-14 days with temperatures above 50°F, followed by sealer application at 28 days. Understanding each step's technical requirements guarantees ideal results and long-term durability.

Expert Highlights

- Excavate 8-10 inches total depth, removing organic material and installing 4 inches of compacted gravel base for proper drainage.

- Compact soil to 95% density using mechanical plate compactors, working in 2-inch layers for optimal stability.

- Install proper forms using 2×4 or 2×6 lumber, securing with stakes and ensuring correct slope for drainage.

- Pour concrete mixture with 0.45-0.50 water-cement ratio, working systematically from uphill to downhill to prevent cold joints.

- Allow concrete to cure for 7-14 days while maintaining moisture and temperature above 50°F, followed by 28 days before sealing.

Site Assessment and Planning

Before any concrete patio installation can begin, a thorough site assessment and detailed planning phase must be completed to guarantee project success. Property owners should evaluate drainage patterns, soil conditions, and existing structures that could impact the project, while considering local building codes and permit requirements.

The assessment phase requires accurate measurements of the proposed patio area, including length, width, and desired thickness of the concrete slab. Professionals typically conduct soil testing to determine load-bearing capacity and identify potential issues like expansive clay or unstable fill material that could compromise the foundation.

During planning, homeowners must decide on design elements such as finish texture, color options, and whether to incorporate features like built-in drainage systems or decorative borders. They should also calculate precise material quantities needed for the project's scope. Working with certified concrete experts ensures proper placement of control joints and optimal concrete mix selection for your specific project needs.

Ground Preparation and Excavation

The excavation phase of concrete patio installation requires careful attention to proper depth requirements, which typically range from 4 to 6 inches for the concrete slab plus an additional 4 inches for the gravel base.

Following excavation, the exposed soil must be thoroughly compacted using mechanical plate compactors or vibratory rollers to achieve a density of at least 95% of the soil's maximum dry density.

The compaction process should be performed in multiple passes across the entire area, with particular focus on the perimeter and any areas that will bear significant weight, ensuring a stable foundation that prevents future settling or cracking of the concrete surface.

With proper maintenance, a well-installed concrete patio can provide up to 30 years of lasting durability and beauty.

Proper Depth Requirements

Proper excavation depth represents a critical foundation for any concrete patio installation, requiring careful consideration of multiple factors to guarantee long-term structural stability.

The standard depth for residential concrete patios typically ranges from 4 to 6 inches, depending on local building codes and intended use.

For areas with freeze-thaw cycles, contractors must excavate below the frost line, which varies by region but generally extends 12 to 48 inches deep.

The base layer, consisting of compacted gravel or crushed stone, should measure 4 to 6 inches thick to assure adequate drainage and support.

When factoring in slope requirements for water runoff, installers should incorporate a minimum grade of 1/8 inch per linear foot, sloping away from any adjacent structures to prevent water accumulation and potential foundation damage.

Soil Compaction Methods

Following accurate depth measurements and excavation, successful soil compaction serves as the cornerstone of durable concrete patio construction, requiring methodical ground preparation through multiple compaction phases.

Professional contractors employ mechanical plate compactors and vibratory rollers to achieve ideal soil density, typically compacting in 2-inch layers until reaching 95% maximum density.

- Inadequate soil compaction can lead to devastating settling issues and cracking

- Proper compaction prevents costly repairs and extends patio longevity

- Quality compaction protects property value and aesthetic appeal

- Well-compacted soil guarantees structural integrity for generations

The compaction process begins with removing organic material and loose soil, followed by adding clean fill material where necessary.

Contractors then use water to achieve ideal moisture content, which aids in reaching maximum soil density through systematic mechanical compression of each layer.

Building Forms and Setting Grades

Setting up precise forms and establishing correct grades represent critical first steps in creating a lasting concrete patio installation. Professional contractors utilize sturdy lumber, typically 2x4s or 2x6s, secured with stakes driven at 4-foot intervals to create rigid boundaries for the concrete pour.

The forms must be level across their length while maintaining a slight slope, typically 1/8 inch per foot, away from the house foundation to guarantee proper drainage. Contractors verify grades using laser levels or transit equipment, checking measurements at multiple points to confirm uniform thickness.

Metal form pins, wooden stakes, and structural support braces work together to prevent form movement during the concrete pour.

The top edges of forms serve as screeding guides, making their precise positioning essential for achieving the desired finished elevation and surface uniformity.

With proper maintenance, a well-installed concrete patio can last up to 30 years while requiring minimal upkeep compared to other materials.

Installing Base Materials and Reinforcement

Before contractors pour any concrete, a properly compacted base of crushed stone or gravel must be installed to provide essential structural support and drainage capabilities.

Most construction professionals recommend a 4-inch minimum depth of aggregate, mechanically compacted to achieve 95% density.

As a Twin Cities contractor with over 10 years of experience, Legacy General Services ensures proper base preparation for every patio project.

With the base prepared, contractors install reinforcement materials to prevent cracking and guarantee structural integrity.

Common reinforcement options include:

- Steel rebar grids, precisely tied and elevated on chairs for ideal positioning

- Welded wire mesh, offering uniform strength distribution across the entire surface

- Fiber reinforcement additives, enhancing concrete's tensile strength

- Steel edge bars, providing additional support along the patio perimeter

The reinforcement materials must maintain proper coverage within the concrete, typically positioned in the middle third of the slab thickness for maximum effectiveness.

Mixing and Pouring Concrete

The mixing phase requires careful attention to achieve the ideal concrete consistency, which typically involves combining Portland cement, aggregates, and water in a 1:2:3 ratio while monitoring slump levels between 2-4 inches.

Workers must blend these materials thoroughly in a mechanical mixer, ensuring uniform distribution and proper hydration of all components without over-mixing, which can weaken the final product.

Once mixed, the concrete should be poured in a controlled, continuous manner, starting from the farthest point and working backward, while maintaining consistent thickness and preventing segregation of aggregates.

For stamped concrete projects, certified team members carefully monitor the mix to ensure optimal workability for creating detailed pattern impressions.

Proper Mix Ratio Steps

Proper concrete mix ratios represent the cornerstone of a successful patio installation, requiring careful attention to proportions and timing throughout the mixing process.

Professional contractors follow established guidelines for combining portland cement, aggregates, and water in precise measurements to achieve ideal strength and workability.

The standard mix ratio for residential patios typically follows these essential steps:

- Begin with clean, measured materials to guarantee consistent batch quality

- Add 1 part portland cement to 2 parts sand and 3 parts gravel

- Incorporate water gradually until reaching a 0.45 to 0.50 water-to-cement ratio

- Mix thoroughly for 5-7 minutes to achieve proper consistency

Once combined, contractors must maintain uniform mixing procedures across multiple batches, testing slump values between 3-5 inches to verify proper workability before placement begins.

Pour With Controlled Flow

Pouring concrete demands precise control over flow rates and placement techniques to achieve ideal coverage and consolidation during the installation process. Contractors must maintain a steady, methodical approach while directing concrete flow from mixer trucks or wheelbarrows to guarantee uniform distribution across the prepared surface area.

| Flow Control Factor | Impact | Best Practice |

|---|---|---|

| Pour Rate | Affects workability | 2-3 ft/minute steady pace |

| Pour Pattern | Distribution uniformity | Serpentine or parallel strips |

| Flow Direction | Material consistency | Pour uphill to downhill |

The installation team should work systematically from one end of the form to another, using hand tools to guide the concrete while maintaining a consistent thickness throughout the pour. This methodical approach helps prevent cold joints, guarantees proper consolidation, and creates ideal conditions for finishing operations.

Finishing Techniques and Surface Textures

Creating beautiful surface textures begins after the concrete has been poured and screeded but before it starts to harden. This critical timing allows contractors to apply various finishing techniques that dramatically impact the patio's final appearance.

The art of concrete finishing demands precise timing – too early or too late, and the perfect surface texture becomes impossible to achieve.

Professional finishers must carefully monitor the concrete's setting process to determine the best moment for texturing.

Common surface finishing options include:

- Smooth trowel finish, providing a classic, refined appearance ideal for outdoor furniture

- Broom finish, creating subtle linear patterns that enhance slip resistance

- Exposed aggregate finish, revealing decorative stones within the concrete mix

- Stamped patterns, replicating natural materials like brick, stone, or slate

The selected texture not only influences aesthetics but also affects maintenance requirements and safety considerations.

This makes proper technique application essential for long-term satisfaction with the finished patio surface.

Expert craftsmanship from skilled professionals ensures each finishing technique is executed with precision and durability.

Proper Curing Methods and Timeline

Once the concrete surface finishing is complete, the critical curing phase must begin immediately to guarantee ideal strength development and prevent premature cracking. The concrete must maintain adequate moisture content for proper hydration, which requires consistent water application or moisture-retaining measures for 7-14 days.

Professional contractors typically employ one of three primary curing methods: water curing through regular spraying, covering with moisture-retaining materials like wet burlap, or applying chemical curing compounds. The temperature should remain above 50°F (10°C) throughout the entire curing period.

During the first 24-48 hours, the concrete requires the most intensive monitoring and moisture maintenance.

After seven days, the concrete will have achieved approximately 70% of its intended strength, though complete curing continues for 28 days to reach maximum structural integrity.

Sealing and Long-Term Maintenance

To maximize the longevity and appearance of a newly installed concrete patio, proper sealing should be performed approximately 28 days after the initial pour, once complete curing has occurred.

Professional-grade penetrating sealers provide superior protection against moisture intrusion, staining, and freeze-thaw damage, while maintaining the concrete's natural appearance.

Regular maintenance guarantees ideal performance and extends the patio's lifespan. Homeowners should implement these essential practices:

- Sweep debris weekly to prevent surface abrasion and maintain aesthetic appeal

- Clean spills immediately using pH-neutral cleaners to avoid staining and deterioration

- Reapply sealer every 2-3 years, depending on weather exposure and wear patterns

- Inspect annually for cracks or damage, addressing repairs promptly to prevent escalation

For extensive cleaning, a pressure washer set at 2,500-3,000 PSI effectively removes accumulated grime without damaging the concrete surface.

Frequently Asked Questions

Can I Install a Concrete Patio During Winter Months?

Installing concrete patios during winter requires extra precautions. Cold temperatures slow curing and can cause damage. Professional contractors use specialized techniques and additives to guarantee proper installation in cold weather.

How Much Will My Utilities Increase With a Heated Concrete Patio?

Operating costs for heated concrete patios typically increase monthly utility bills by $100-300 during winter months, depending on size, local energy rates, and temperature settings.

Will Tree Roots Eventually Damage My Concrete Patio?

Tree roots can indeed damage concrete patios over time, causing cracks and uneven surfaces. Installing root barriers and maintaining proper distance from large trees helps prevent this common problem.

Can I Match My Existing Concrete Patio Color With a New Addition?

Matching existing concrete color is possible through color hardeners, stains, or integral pigments. Professional concrete contractors can analyze the old surface and recommend suitable color-matching solutions.

Does a Concrete Patio Affect My Home's Resale Value?

A well-designed concrete patio typically increases home resale value by enhancing outdoor living space. Most homeowners recover 50-80% of installation costs through improved property value and curb appeal.

Expert Final Thougts

A properly installed concrete patio requires careful attention to each phase, from initial site preparation through final curing and sealing. Following industry best practices for ground preparation, reinforcement, concrete mixing, and finishing techniques guarantees peak strength and longevity. With proper maintenance including periodic cleaning and resealing, a well-constructed concrete patio can provide decades of durable, functional outdoor living space while maintaining its aesthetic appeal and structural integrity.

Concrete Patio Design Options Modern, Traditional, Rustic

Concrete patio designs offer three distinct style categories: modern, traditional, and rustic. Modern designs feature clean lines, geometric patterns, and minimalist aesthetics with exposed aggregate finishes. Traditional styles incorporate classic stamped patterns like herringbone and running bond brick, while rustic designs utilize specialized stamping techniques that replicate natural materials. Each style can be enhanced through various coloring methods, including integral pigments and acid stains, with proper sealing ensuring longevity. The extensive range of customization options creates limitless possibilities for transforming outdoor spaces.

Expert Highlights

- Modern concrete patios feature clean lines, geometric patterns, and minimalist designs with metallic epoxy coatings and LED lighting systems.

- Traditional designs incorporate stamped patterns like running bond brick and herringbone, with exposed aggregate finishes for durability.

- Rustic concrete patios replicate natural materials through specialized stamping techniques that create wood grain, slate, or river rock textures.

- All design styles can be enhanced with acid stains, water-based stains, or integral pigments for customized color variations.

- Proper sealing every three years maintains appearance and protects decorative finishes across modern, traditional, and rustic designs.

Modern Design Elements for Contemporary Concrete Patios

When designing a contemporary concrete patio, modern aesthetic elements have evolved considerably beyond traditional plain gray slabs into sophisticated architectural features that can transform outdoor spaces.

Today's designs incorporate clean lines, geometric patterns, and minimalist elements that reflect current architectural trends.

Modern design elegantly merges simplicity with structure, using clean geometric forms to create sophisticated outdoor spaces that embrace contemporary aesthetics.

Popular modern features include exposed aggregate finishes, metallic epoxy coatings, and integrated LED lighting systems that create dramatic evening ambiance.

Designers frequently utilize large-format scoring patterns, often in 4×4 or 6×6-foot squares, to establish visual rhythm and spatial flow.

Contemporary concrete patios also embrace technological innovations, such as photocatalytic surfaces that actively break down air pollutants, and specialized sealers that provide UV protection while maintaining the concrete's natural appearance.

These advanced materials allow for both aesthetic appeal and practical functionality in modern outdoor living spaces.

Working with skilled contractors ensures proper control joint placement and expert finishing techniques that enhance the overall modern design aesthetic.

Traditional Concrete Patio Patterns and Finishes

Traditional concrete patio designs offer timeless appeal through well-established patterns and finishing techniques that have withstood decades of architectural evolution. Classic stamped patterns, including running bond brick, herringbone, and ashlar slate, continue to dominate residential installations across North America.

Exposed aggregate finishes, which reveal decorative stones within the concrete matrix, provide durability while maintaining an elegant appearance that complements traditional home architecture.

Scored concrete patterns, typically featuring 4-foot by 4-foot squares with deep control joints, create clean geometric layouts that resist cracking while preserving visual symmetry.

Salt finish texturing, achieved by broadcasting rock salt before the concrete sets, delivers subtle variation in surface texture without compromising the refined appearance expected in traditional design, making it particularly suitable for poolside applications where slip resistance is essential.

With certified expert installation, these traditional finishes can maintain their beauty and functionality for up to 30 years with proper maintenance.

Rustic Charm: Textured and Stamped Concrete Options

Creating rustic appeal through concrete requires specialized stamping and texturing techniques that faithfully replicate natural materials, such as weathered wood, fractured stone, or hand-chiseled slate.

| Texture Type | Depth Range | Application Method |

|---|---|---|

| Wood Grain | 1/4" – 1/2" | Deep Stamping |

| Slate Pattern | 1/8" – 3/8" | Skin Stamping |

| River Rock | 3/8" – 5/8" | Mat Imprinting |

Professional contractors utilize specialized mats and tools to achieve authentic-looking textures, pressing patterns into semi-cured concrete at precise depths and angles. The process requires careful timing and experienced application to guarantee proper pattern transfer and structural integrity.

These rustic finishes can be enhanced through strategic color integration, using acid stains, powder release agents, and integral pigments that create variegated tones resembling natural aging and weathering processes.

With proper maintenance routines, stamped concrete surfaces can maintain their rustic beauty for over 25 years.

Color Choices and Staining Techniques

Numerous coloring and staining options allow homeowners to transform ordinary concrete patios into rich, personalized outdoor spaces. Concrete colorants include integral pigments mixed directly into wet concrete, surface-applied stains, and dyes that penetrate the material's surface.

Acid stains create variegated, natural-looking effects through chemical reactions with the concrete's minerals, producing earth-toned hues ranging from tans and browns to deep russet and copper patinas. Water-based stains offer a broader color palette, including vibrant blues, greens, and modern grays, while maintaining the concrete's natural variations.

Professional concrete artisans often combine multiple staining techniques, applying layers of color to achieve depth and dimension. Antiquing releases, color hardeners, and specialized sealers further enhance the finished appearance while providing essential protection against weathering and wear. Legacy General Services provides expert staining and coloring services for residential and commercial properties throughout the Twin Cities metropolitan area.

Integrating Borders and Decorative Accents

Beyond the foundational color treatments, borders and decorative accents serve as defining architectural elements that frame and enhance concrete patio designs.

Common border treatments include stamped patterns, inlaid tiles, contrasting concrete bands, and decorative aggregate strips that establish visual boundaries while adding sophistication to the overall design.

Sophisticated border elements transform ordinary concrete patios into elegant outdoor spaces through artful combinations of patterns, tiles and decorative bands.

Skilled contractors can integrate numerous decorative elements, including medallions, compass roses, and geometric shapes, which create focal points within the patio space.

These accents, often achieved through techniques such as scoring, stenciling, or embedding materials, can be customized to complement surrounding architecture and landscaping features.

Modern installations frequently incorporate LED lighting strips, metal inlays, or glass aggregate bands along borders, providing both aesthetic appeal and practical functionality for evening entertainment while defining changeover zones between different patio areas.

With proper maintenance and professional sealing every three years, these decorative borders and accents will maintain their visual appeal while protecting against moisture damage.

Seamless Indoor-Outdoor Living Space Solutions

To achieve a harmonious change between interior and exterior spaces, modern concrete patio designs increasingly incorporate architectural elements that blur traditional boundaries between indoors and out.

Flush thresholds, continuous flooring patterns, and matching concrete finishes create visual flow, while large sliding glass doors or folding wall systems eliminate physical barriers.

Strategic design elements, such as covered connections and weather-resistant materials, enable year-round functionality. Concrete surfaces can be color-matched to interior flooring, while integrated drainage systems and proper grading guarantee seamless changes remain practical.

Level surfaces throughout facilitate accessibility and furniture placement.

Lighting design plays an essential role, with recessed fixtures and understated ambient illumination maintaining consistency between spaces.

Temperature control features, including radiant heating and cooling zones, extend comfortable living conditions across the merged environments.

With proper maintenance and care, these durable concrete surfaces can provide up to 30 years of seamless indoor-outdoor living enjoyment.

Frequently Asked Questions

How Long Does a Concrete Patio Typically Last Before Requiring Major Repairs?

A properly installed and maintained concrete patio typically lasts 20-30 years before requiring major repairs. Regular sealing and addressing minor cracks early helps extend its serviceable lifespan.

Can Existing Concrete Patios Be Resurfaced Instead of Completely Replaced?

Most concrete patios can be successfully resurfaced if the base is structurally sound. Resurfacing involves applying a new layer of concrete overlay, offering a cost-effective alternative to complete replacement.

What Maintenance Is Required to Keep a Concrete Patio Looking New?

Regular cleaning, sealing every 2-3 years, prompt stain removal, and crack repair help maintain concrete patios. Homeowners should avoid harsh chemicals and address drainage issues to prevent deterioration.

How Soon Can You Use a Newly Installed Concrete Patio?

After pouring, concrete needs at least 24-48 hours before light foot traffic. For furniture and heavy use, homeowners should wait 7-10 days. Full curing takes about 28 days.

Does Weather Affect Concrete Patio Installation and Curing Time?

Weather considerably impacts concrete patio installation and curing. Temperature, humidity, wind, and precipitation can affect setting times, with ideal conditions being moderate temperatures and no rain.

Expert Final Thougts

Concrete patios offer remarkable versatility through modern, traditional, and rustic design approaches, each providing distinct aesthetic and functional benefits. Through careful selection of patterns, textures, colors, and decorative elements, homeowners can create outdoor spaces that seamlessly extend their living areas while reflecting personal style. Whether employing sleek contemporary lines, classic geometric patterns, or natural-looking finishes, concrete remains an adaptable, durable, and cost-effective foundation for exceptional outdoor living spaces.