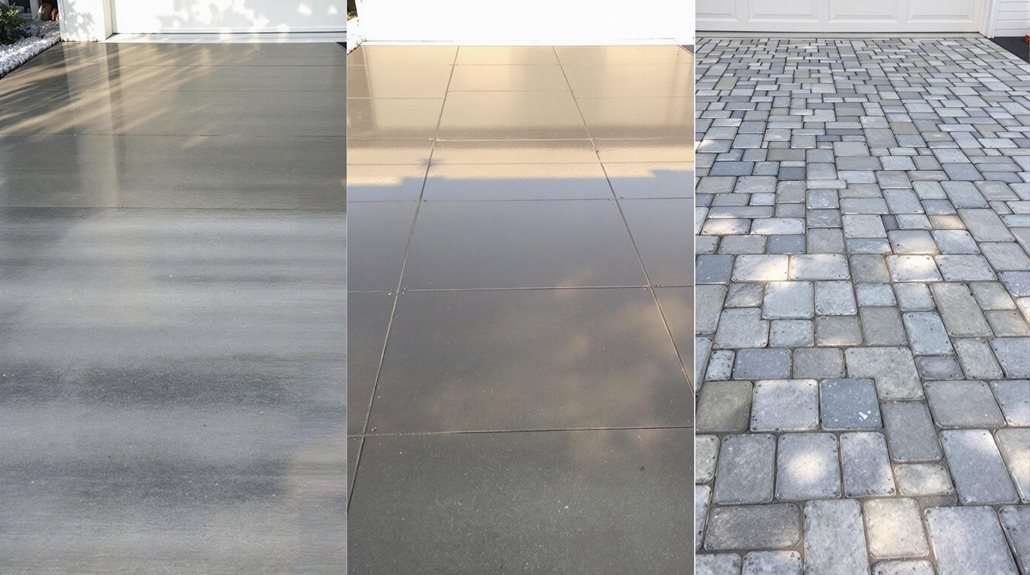

Concrete Driveways Types Brushed, Polished, Stamped

Concrete driveways come in three main finish types, each offering distinct benefits. Brushed concrete provides superior slip resistance and minimal maintenance at $6-8 per square foot, while polished concrete delivers a sophisticated reflective surface requiring resealing every 2-3 years. Stamped concrete, though more expensive at $12-20 per square foot, replicates natural materials like brick and stone through intricate patterns and custom coloring. Understanding the specific features of each finish type enables ideal selection based on budget, aesthetics, and practical needs.

Expert Highlights

- Brushed concrete driveways offer superior slip resistance and minimal maintenance, costing 15-20% less than decorative options with a 30-year lifespan.

- Polished concrete creates a glass-like reflective finish that resists stains and moisture but requires resealing every 2-3 years.

- Stamped concrete replicates natural materials like brick and stone, with custom color options and pattern choices for enhanced aesthetic appeal.

- Installation costs range from $6-8 per square foot for brushed concrete to $12-20 for premium stamped finishes.

- Maintenance requirements vary significantly: brushed needs annual washing, polished needs quarterly cleaning, and stamped requires semi-annual cleaning with resealing.

Understanding the Basic Types of Concrete Driveway Finishes

Concrete driveways offer homeowners a range of distinctive finishing options that can dramatically affect both aesthetics and functionality.

Each finish type provides specific advantages regarding traction, durability, and visual appeal, allowing property owners to select the most suitable option for their needs.

Choose your concrete finish wisely – each style offers unique benefits in grip, longevity, and looks to match your property's requirements.

The most common finishes include brushed (also known as broom-finished), which creates linear textures for enhanced grip; smooth-troweled, which provides a sleek, modern appearance; exposed aggregate, revealing decorative stones within the concrete matrix; and salt-finished, producing a subtle, stippled texture through chemical reaction.

Additionally, modern finishing techniques encompass polished concrete, which yields a glossy, reflective surface, and stamped patterns that can replicate the appearance of natural materials such as brick, stone, or slate through specialized imprinting processes.

With proper maintenance, concrete driveways can maintain their aesthetic appeal and structural integrity for up to 30 years while requiring minimal upkeep compared to alternative materials.

Benefits and Features of Brushed Concrete Driveways

Brushed concrete driveways, widely recognized as one of the most practical and cost-effective finishing options, combine superior slip resistance with minimal maintenance requirements.

The brushing technique, applied while the concrete is still wet, creates shallow parallel lines that enhance traction while facilitating water runoff during inclement weather.

This finish type typically costs 15-20% less than decorative alternatives, making it an economical choice for homeowners seeking durability without sacrificing functionality.

The textured surface effectively conceals minor imperfections and small cracks that may develop over time, while the uniform appearance complements various architectural styles.

Professional contractors can achieve different degrees of texture depth, ranging from light to medium, allowing property owners to customize the finish according to their specific needs and local climate conditions.

With proper maintenance and professional installation, concrete sidewalks last up to 30 years while maintaining their slip-resistant properties and aesthetic appeal.

The Appeal of Polished Concrete Surfaces

Polished concrete driveways represent a sophisticated choice that brings sleek, modern aesthetics to residential and commercial properties through their glass-like, reflective finish.

The mechanically ground and polished surface, achieved through progressively finer diamond-embedded discs, creates an exceptionally smooth, low-maintenance surface that resists staining, moisture penetration, and daily wear.

Beyond its practical durability benefits, a polished concrete driveway can markedly enhance property values by providing an upscale, contemporary appearance that distinguishes a property from conventional concrete finishes.

Unlike traditional concrete surfaces, surface resealing maintenance is required every 2-3 years to preserve the polished finish and protect the investment.

Sleek Modern Design Appeal

When homeowners seek to create a distinctly contemporary aesthetic for their properties, polished concrete surfaces deliver an unmistakably sleek and sophisticated appearance. The minimalist nature of polished concrete, characterized by its smooth, reflective finish and uniform color gradients, aligns perfectly with modern architectural principles.

The clean lines and industrial-inspired look of polished concrete driveways complement contemporary home designs, particularly those featuring glass, steel, and geometric elements. Professional contractors achieve this refined appearance through multiple grinding stages, progressing from coarse to fine diamond abrasives, followed by densifier application and final polishing.

These surfaces create visual continuity between indoor and outdoor spaces, a hallmark of modern design, while the subtle variations in aggregate exposure and sheen levels add understated visual interest without compromising the overall modernist aesthetic.

Low Maintenance Durability Benefits

Among the most compelling advantages of polished concrete surfaces, their exceptional durability and minimal maintenance requirements stand out as primary benefits for property owners.

Professional contractors consistently recommend these surfaces for their lasting value and resilience against daily wear.

- Annual maintenance costs average 60% lower than traditional flooring options

- Polished surfaces resist staining, chemical damage, and moisture penetration

- The densified surface eliminates the need for waxing or coating treatments

- Life expectancy extends beyond 20 years with proper installation

The mechanical polishing process creates a densified surface that withstands heavy traffic while requiring only routine dust mopping and occasional damp cleaning.

This enhanced durability results from the microscopic refinement of the concrete's surface, which closes pores and creates an almost impenetrable barrier against environmental factors and daily use.

Enhanced Property Value Impact

Installing a professionally polished concrete surface can significantly boost a property's market value, with real estate assessments indicating an average 8-12% increase in overall home valuation compared to standard flooring options.

The enhanced aesthetic appeal of polished concrete, characterized by its reflective surface and sophisticated finish, creates a modern, upscale appearance that prospective buyers increasingly seek in contemporary homes.

The material's durability and low maintenance requirements further contribute to its value-adding potential, as buyers recognize the long-term cost benefits.

Professional real estate agents frequently highlight polished concrete surfaces as premium features during property showings, emphasizing their sustainable qualities, energy efficiency through better light reflection, and superior longevity compared to traditional materials.

These attributes consistently translate into faster property sales and stronger negotiating positions in competitive markets.

Exploring Stamped Concrete Patterns and Designs

Stamped concrete driveways offer homeowners an extensive range of patterns that can replicate natural materials like brick, slate, and cobblestone through specialized imprinting techniques.

The design possibilities extend beyond pattern selection to include integral colors, surface-applied stains, and antiquing agents that create rich, multi-tonal effects reminiscent of natural stone or weathered surfaces.

Installation requires precise timing and skilled craftsmanship, as contractors must carefully coordinate the concrete pour, color application, and pattern stamping while the surface maintains ideal plasticity for accepting detailed impressions.

With proper installation and maintenance, these decorative stamped concrete surfaces can provide up to 30 years of durable, aesthetically pleasing service.

Popular Pattern Choices

Modern homeowners seeking to enhance their driveways have access to an extensive array of stamped concrete patterns and designs, each capable of transforming an ordinary surface into an architectural focal point.

Among the most sought-after stamped concrete patterns, these selections consistently rank at the top of installation requests:

- Ashlar slate patterns, featuring interlocking rectangular stones of varying sizes, creating a sophisticated old-world appearance.

- Herringbone brick designs, incorporating classic 45-degree angles that add visual movement and traditional charm.

- Natural stone textures, including flagstone and cobblestone impressions, which replicate high-end materials at a fraction of the cost.

- European fan patterns, displaying elegant curved designs that radiate outward in semi-circular formations, particularly suitable for circular driveways and large entrance areas.

Coloring and Design Options

Beyond the foundational patterns that define stamped concrete's texture and layout, the application of color transforms these surfaces through an expansive palette of customization options, which can dramatically alter the driveway's aesthetic impact and complement a property's architectural elements.

Color integration methods include integral pigments mixed directly into wet concrete, surface-applied color hardeners, antiquing agents, and acid stains that create variegated, multi-tonal effects.

Homeowners can select from earth-toned terracottas and sandy beiges to sophisticated grays and deep charcoals, with custom color matching available for precise architectural coordination.

Advanced coloring techniques allow for realistic simulation of natural materials, including weathered stone, classic brick, and exotic slate, while protective sealers enhance color retention and maintain the driveway's appearance through years of exposure to UV rays and environmental factors.

Installation Timing and Process

The precise timing and systematic execution of concrete pattern installation involves three critical phases that must be carefully coordinated within a narrow working window.

Each phase requires specific environmental conditions and expert timing to achieve ideal results.

- Initial pour and screeding must occur when temperatures range between 50-85°F.

- Pattern stamping begins during the critical "thumbprint stage" of curing.

- Color hardener application follows immediately after surface water evaporation.

- Final sealing occurs after 28 days of complete curing.

Professional installers carefully monitor weather conditions, ambient temperature, and concrete consistency throughout the process, as these factors considerably impact the finished product's durability and appearance.

The entire installation typically requires 6-8 hours of continuous work, followed by protective covering and controlled curing conditions for ideal results.

Cost Comparison Between Different Concrete Finishes

When evaluating different concrete finishes for a driveway, costs can vary greatly based on complexity, materials, and labor requirements.

Basic brushed concrete typically ranges from $6 to $8 per square foot, representing the most economical option for homeowners seeking durability with minimal aesthetic enhancement.

Mid-range finishes, such as exposed aggregate or salt-finished concrete, generally cost between $8 and $12 per square foot, offering increased visual appeal through texture variations and specialized finishing techniques.

These options provide an excellent balance between aesthetics and affordability.

Premium finishes, including stamped or stained concrete, command the highest prices, ranging from $12 to $20 per square foot.

While these finishes replicate the appearance of natural stone or brick patterns, the additional labor, specialized tools, and materials required contribute greatly to their elevated cost structure.

Concrete patio contractors can help determine the most suitable finish while ensuring proper installation and long-term durability.

Maintenance Requirements for Each Driveway Type

Maintaining different concrete driveway finishes requires varying levels of effort, specialized cleaning methods, and protective treatments to preserve their functional and aesthetic qualities over time. Each surface type demands specific maintenance protocols to guarantee longevity and appearance retention.

- Brushed concrete requires minimal maintenance, needing only periodic sweeping and annual pressure washing to remove debris and prevent staining.

- Polished concrete surfaces demand quarterly cleaning with pH-neutral cleaners and biennial resealing to maintain their reflective qualities.

- Stamped concrete necessitates semi-annual cleaning, resealing every 2-3 years, and prompt stain removal to protect the pattern detail.

- Exposed aggregate finishes need gentle cleaning methods, annual sealing, and careful snow removal to prevent aggregate loosening.

Professional cleaning services may be necessary for best results, particularly for more intricate finishes requiring specialized equipment or expertise. Our Twin Cities contractor team provides comprehensive maintenance services backed by over 10 years of concrete industry experience.

Choosing the Right Finish for Your Climate and Usage

Selecting an appropriate concrete driveway finish requires careful consideration of regional weather patterns, temperature fluctuations, and anticipated usage patterns, as these factors significantly impact the surface's long-term performance and durability.

In cold climates, broom-finished or exposed aggregate surfaces provide essential traction during icy conditions, while smooth-troweled finishes perform better in moderate climates where ice is less common.

Areas experiencing frequent freeze-thaw cycles benefit from sealed, stamped patterns that help prevent moisture penetration and subsequent surface deterioration.

Usage intensity also determines ideal finish selection. High-traffic driveways serving multiple vehicles benefit from robust, textured finishes that resist wear patterns, while decorative surfaces with detailed patterns may be more suitable for limited-use residential applications where aesthetic appeal takes precedence over heavy-duty performance requirements.

Frequently Asked Questions

How Long Should I Wait Before Parking on a New Concrete Driveway?

Parking on a new concrete driveway requires patience. Most experts recommend waiting at least 7 days before light vehicles and 28 days for heavy vehicles to guarantee proper curing.

Can Concrete Driveways Be Installed Over Existing Asphalt?

Installing concrete over asphalt is possible but not recommended. The asphalt must be stable and properly prepared. Most professionals advise removing old asphalt first for better long-term results.

What Causes Concrete Driveways to Crack During the First Year?

Common causes of first-year concrete driveway cracks include improper curing, rapid moisture evaporation, poor soil compaction, incorrect control joint placement, and excessive water in the mix.

Is It Possible to Change the Color of My Concrete Driveway Later?

Homeowners can modify their driveway's color through concrete staining or painting. Both options offer lasting results when properly applied, though staining penetrates deeper and typically provides more natural-looking finishes.

How Does Rock Salt Affect Different Types of Concrete Driveway Finishes?

Rock salt can deteriorate all concrete surfaces, but polished and stamped finishes are especially vulnerable. The salt's chemical reaction breaks down concrete's surface, causing pitting and erosion over time.

Expert Final Thougts

The choice between brushed, polished, and stamped concrete driveways ultimately depends on a careful evaluation of budget, maintenance capacity, climate conditions, and aesthetic preferences. While brushed concrete offers reliable functionality at lower cost, polished surfaces provide sophisticated durability, and stamped patterns deliver customizable curb appeal. Understanding these key differences allows homeowners to select the most suitable concrete finish that will serve their specific needs for years to come.