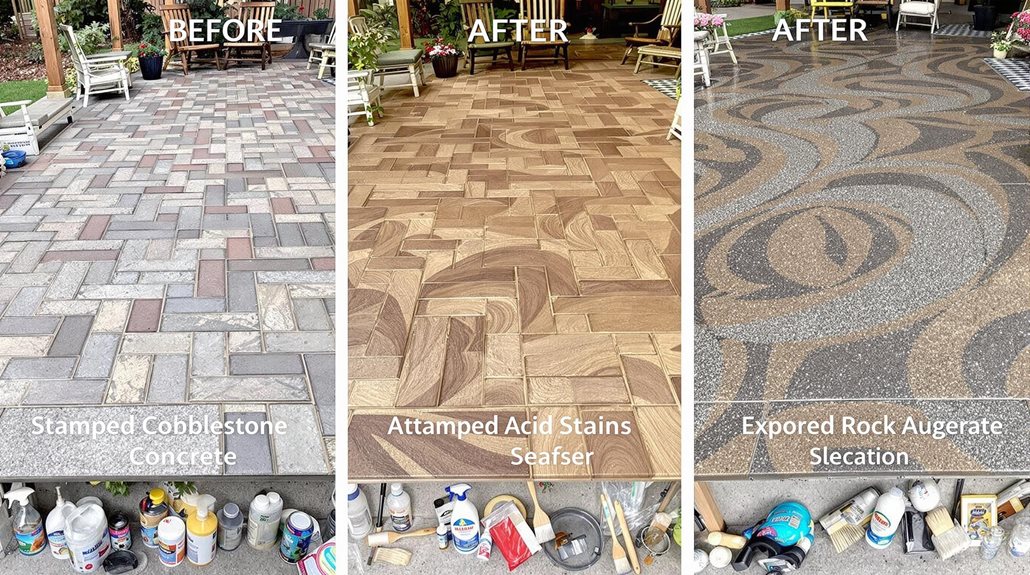

Concrete Patio Material Choices Stamped, Stained, Exposed Aggregate

Modern concrete patios offer three primary decorative finishes: stamped patterns that replicate natural stone or brick through textured molds, acid staining that creates variegated earth-tone colors through chemical reactions, and exposed aggregate that reveals decorative stones embedded within the surface. Each option carries distinct maintenance requirements and costs, with stamped concrete ranging $15-20 per square foot, staining at $8-12, and exposed aggregate at $10-15. Understanding the unique characteristics of each finish enables best selection based on aesthetic preferences and regional climate conditions.

Expert Highlights

- Stamped concrete replicates natural materials like stone and brick, requiring coordinated mixing and timing for successful pattern application.

- Acid staining creates unique earth-toned colors through chemical reactions, offering diverse color intensities for sophisticated finishes.

- Exposed aggregate reveals decorative stones like river rock or granite chips through pressure washing and chemical retarders.

- Standard gray concrete costs $6-8 per square foot, while decorative finishes can reach $15-30 per square foot.

- All decorative concrete options require specific maintenance schedules, including annual sealing, pressure washing, and regular cleaning.

Understanding Basic Concrete Patio Options

Homeowners exploring concrete patio options must first understand the fundamental choices available regarding basic materials, finishes, and construction methods.

Traditional concrete patios utilize Portland cement mixed with aggregates and water, creating a durable surface that can last decades when properly installed and maintained.

Traditional concrete patios blend Portland cement, aggregates, and water to create long-lasting outdoor surfaces that endure through proper installation and maintenance.

The basic installation process involves preparing a stable subgrade, installing proper drainage and reinforcement, then pouring and finishing the concrete mixture.

While standard gray concrete remains popular due to its affordability and versatility, modern techniques allow for enhanced aesthetic appeal through various finishing methods.

Concrete thickness typically ranges from 4 to 6 inches for residential patios, with thicker slabs required for areas supporting heavy loads or experiencing freeze-thaw cycles.

The concrete mix design must achieve a minimum compressive strength of 3,500 PSI for peak durability and crack resistance.

Working with licensed contractors ensures reliable installation and proper construction techniques from start to finish.

The Art and Appeal of Stamped Concrete

Stamped concrete transforms ordinary concrete patios into artistic surfaces that can replicate the look of natural stone, brick, slate, or even wood grain through specialized patterns and texturing techniques.

The installation process combines colored concrete placement, carefully-timed surface pressing with specialized rubber mats or forms, and skilled finishing work to create three-dimensional impressions that mimic high-end materials.

Professional contractors must coordinate multiple steps precisely, including proper concrete mixing ratios, color hardener application, release agent usage, and stamping timing to achieve ideal pattern depth and authentic-looking textures.

With proper maintenance practices, stamped concrete surfaces can maintain their beauty and structural integrity for over 25 years.

Stamped Pattern Design Options

When exploring the artistic possibilities of concrete patios, stamped patterns emerge as one of the most versatile and aesthetically pleasing design options available to modern construction. The selection of patterns ranges from natural stone textures, including slate, flagstone, and cobblestone, to geometric designs and repeating motifs that complement various architectural styles.

Professional contractors can implement intricate designs using specialized tools and forms, creating authentic-looking textures that mimic high-end materials at a fraction of the cost. Popular options include ashlar cut stone, which features a classic rectangular pattern, and seamless texture skins that replicate weathered wood or natural rock formations.

The depth and complexity of these patterns can be further enhanced through strategic coloring techniques, including integral pigments, color hardeners, and release agents, which add dimension and realism to the finished surface.

Installation and Finishing Process

The intricate process of concrete patio installation begins with thorough site preparation, including proper grading, compaction of the base material, and installation of forms to contain the wet concrete mixture.

Reinforcement materials, such as steel mesh or fiber additives, are positioned to prevent cracking and guarantee structural integrity.

Once the concrete is poured and leveled, contractors apply a release agent to prevent the stamping tools from adhering to the surface.

The concrete must reach the ideal consistency before skilled technicians carefully press specialized rubber mats or stamps into the semi-hardened surface to create the desired pattern and texture.

Final finishing steps include cleaning excess release agent, applying concrete sealers for protection, and allowing proper curing time, typically 24-48 hours for foot traffic and 7-10 days for vehicle traffic.

Color Variations Through Acid Staining

Transforming ordinary concrete into rich, variegated surfaces becomes possible through acid staining, a chemical reaction process that permanently alters the concrete's appearance.

The stains, typically containing metallic salts suspended in an acidic water-based solution, penetrate the concrete surface and react with calcium hydroxide, creating unique earth-toned colors.

Chemical artistry unfolds as metallic salts merge with concrete's calcium hydroxide, transforming gray surfaces into rich, earthen masterpieces.

The resulting patterns emerge in warm browns, terra cottas, and subtle blues or greens, depending on the specific chemical compounds used in the staining process. Multiple applications can create layered effects, while varying the dilution ratios affects color intensity. Environmental factors, such as concrete age and surface conditions, influence the final outcome.

Professional applicators often combine different staining techniques, including spray methods and brush applications, to achieve sophisticated marbling effects that mimic natural stone or leather textures.

With expert craftsmanship from skilled professionals, these decorative finishes can transform both residential and commercial concrete installations into stunning architectural features.

Exposed Aggregate: Natural Beauty Revealed

Exposed aggregate installation involves multiple steps, beginning with placing and screeding the concrete mix, followed by washing away the surface mortar to reveal decorative stones beneath.

The process allows contractors to create varied patterns through stone selection and placement techniques, incorporating natural river rock, granite chips, or colored glass in sizes ranging from 1/8 to 3/4 inch.

Designers can achieve striking visual effects by combining different aggregate materials and colors, from earth-toned pebbles that create a naturalistic appearance to vibrant glass chips that produce a modern, architectural statement.

As a certified team member of Legacy General Services, our experts ensure pristine installation and superior quality control throughout the exposed aggregate process.

Installation Steps and Methods

Creating an exposed aggregate patio requires a systematic, multi-step approach that begins well before the concrete is poured.

Initial site preparation involves grading, compacting the soil, and installing proper forms and reinforcement mesh to guarantee structural integrity.

Once the concrete mix is poured to the desired thickness, contractors must wait for the precise moment when the surface begins to set.

At this critical stage, a chemical retarder is applied to delay surface curing while the underlying concrete hardens.

After approximately 24 hours, workers carefully pressure wash the surface to expose the decorative aggregate.

The final steps include allowing the concrete to cure completely for 7-10 days, applying a protective sealer to enhance the aggregate's appearance, and installing control joints to prevent random cracking.

This methodical process guarantees a durable, aesthetically pleasing result.

Patterns and Color Options

Through careful selection of aggregates and matrix colors, exposed aggregate patios offer an extensive range of aesthetic possibilities that blend natural sophistication with practical durability.

Homeowners can choose from river rock, granite chips, or even recycled glass aggregates in various sizes and hues, creating distinctive visual textures that complement surrounding landscapes.

The matrix concrete itself can be tinted using integral color admixtures or surface-applied stains in earth tones, warm grays, or bold terracotta shades.

When combined with different exposure depths and seeding patterns, these options produce unique surface effects ranging from subtle to dramatic.

Professional contractors often create custom aggregate blends, mixing different sizes and colors of stone to achieve specific design objectives while maintaining ideal surface consistency and structural integrity throughout the installation process.

Maintenance Requirements for Different Finishes

While different concrete patio finishes can greatly enhance outdoor spaces, each type requires specific maintenance protocols to preserve its appearance and structural integrity over time.

Selecting the right concrete patio finish demands commitment to proper maintenance practices to ensure lasting beauty and performance.

The level of maintenance needed varies considerably based on the finish type, environmental conditions, and usage patterns.

- Stamped concrete surfaces need annual sealing and occasional pressure washing to prevent staining and maintain color vibrancy.

- Exposed aggregate finishes require periodic cleaning with specialized cleaners to remove organic debris from between stones.

- Stained concrete demands biannual sealing and prompt spill cleanup to protect the coloring agents.

- Polished concrete surfaces benefit from weekly dust mopping and monthly wet cleaning with pH-neutral cleaners.

- Smooth-troweled finishes need regular sweeping and occasional degreasing to prevent slip hazards.

Regular inspection and prompt repairs of any cracks or damage help maintain long-term durability across all finish types.

With proper care and maintenance, concrete surfaces can provide 30 years of service when professionally installed and maintained according to recommendations.

Cost Comparisons Across Patio Styles

The cost variation between basic and premium concrete patio finishes can be substantial, with plain gray concrete starting at $6-8 per square foot while decorative options often exceed $15-20 per square foot.

Premium finishes, such as stamped patterns, exposed aggregate, or stained concrete, typically command higher prices due to increased labor requirements, specialized tools, and more expensive materials.

Installation complexity also impacts overall costs, as intricate designs requiring multiple colors, detailed patterns, or custom scoring can push prices toward $25-30 per square foot or higher in many markets.

With proper maintenance and professional installation by certified concrete experts, these premium concrete finishes can maintain their beauty and durability for up to 30 years.

Average Costs Per Square

Selecting an appropriate concrete patio style requires careful consideration of material costs, which can vary considerably across different options and finishes. Industry averages indicate significant price variations between basic and premium installations, with regional factors affecting final costs.

- Plain concrete patios typically range from $6 to $12 per square foot

- Colored concrete increases costs to $12 to $18 per square foot

- Stamped patterns elevate pricing to $15 to $25 per square foot

- Exposed aggregate installations average $12 to $20 per square foot

- Custom designs with multiple colors and patterns can exceed $30 per square foot

These price points reflect complete installation costs, including base preparation, reinforcement materials, and finishing work.

Labor typically represents 40-60% of total costs, while material expenses vary based on concrete grade, color additives, and surface treatment complexity.

Premium Vs Basic Options

Comparing premium and basic concrete patio installations reveals considerable cost differentials across various style categories, with luxury options often commanding prices 200-300% higher than standard alternatives.

Premium finishes, such as stamped patterns with multiple colors and sealed surfaces, typically range from $15-25 per square foot, while basic broom-finished concrete averages $6-8 per square foot.

High-end treatments incorporate advanced materials like color hardeners, release agents, and protective sealers, which considerably enhance both aesthetics and durability. These premium installations often feature intricate patterns, seamless texturing, and carefully controlled curing processes that require specialized expertise.

Basic installations, while functional and durable, utilize standard gray concrete with simple finishing techniques, making them an economical choice for budget-conscious property owners who prioritize function over decorative elements.

Weather Resistance and Durability Factors

When constructing a concrete patio that will endure for decades, weather resistance and durability factors play crucial roles in material performance and longevity.

Environmental conditions, including freeze-thaw cycles, UV exposure, and precipitation patterns, considerably impact concrete's structural integrity and appearance over time.

Key factors affecting concrete patio durability include:

- Compressive strength rating, typically 3,000 to 4,000 PSI for residential applications

- Air-entrainment percentage, ideally 5-7% for freeze-thaw resistance

- Water-to-cement ratio, ideally 0.45-0.50 for maximum durability

- Surface sealant type and reapplication schedule

- Proper installation of control joints every 8-12 feet

Professional contractors incorporate these durability considerations during both the design and implementation phases, ensuring the finished patio withstands local climate challenges while maintaining its aesthetic appeal through seasonal changes and years of use.

Installation Methods and Timeline

A successful concrete patio installation requires careful planning, precise execution, and adherence to specific timelines throughout multiple phases of construction.

The process typically begins with site preparation, including grading, compaction, and installation of forms and reinforcement, which takes 1-2 days.

Proper site preparation forms the foundation of any successful concrete project, ensuring stability through careful grading, thorough compaction and strategic reinforcement placement.

The concrete pour represents the most critical phase, requiring coordination of delivery trucks and finishing crews to complete the placement within a 2-4 hour window.

After screeding and floating, contractors must wait for the ideal moment to begin finishing operations, including texturing and edging.

The curing phase demands strict attention to temperature and moisture conditions over 7-28 days.

During this period, the concrete should be kept consistently damp and protected from extreme weather conditions, while bearing no significant weight or traffic.

Design Patterns and Border Options

Modern concrete patios offer homeowners an extensive array of design patterns and decorative border options that transform basic slabs into sophisticated outdoor living spaces.

Common design elements incorporate geometric shapes, natural stone patterns, and distinctive border treatments that define spaces and create visual interest.

Professional contractors can implement numerous artistic patterns through:

- Stamped impressions mimicking brick, slate, or cobblestone textures

- Scored patterns creating clean lines and symmetrical sections

- Stenciled designs featuring intricate medallions or custom motifs

- Exposed aggregate borders providing textural contrast

- Saw-cut patterns forming precise geometric shapes

Border treatments often feature contrasting colors or textures that frame the main patio area, incorporating detailed edge work such as bullnose finishing or rolled edges.

These design elements can complement existing architecture while establishing distinct outdoor zones for various activities.

Selecting the Right Finish for Your Climate

Beyond aesthetic design choices, climate conditions considerably influence the selection of concrete patio finishes, as different surface treatments perform differently under varying weather patterns and environmental stresses.

| Climate Type | Recommended Finish | Key Benefits |

|---|---|---|

| Hot/Arid | Smooth Trowel | Reflects heat, minimizes cracking |

| Wet/Humid | Broom Finish | Enhanced traction, water drainage |

| Freeze/Thaw | Salt Finish | Slip resistance, ice management |

For regions experiencing significant temperature fluctuations, penetrating sealers provide superior protection against moisture infiltration and freeze-thaw damage, while maintaining the concrete's ability to breathe. Coastal environments benefit from densifiers and water-repellent treatments that protect against salt exposure and humidity, extending the patio's longevity through enhanced chemical resistance and reduced efflorescence.

Frequently Asked Questions

Can Concrete Patios Be Installed Over Existing Concrete Slabs?

Most homeowners can successfully overlay new concrete onto existing slabs if the base is structurally sound, properly prepared, and has adequate drainage. Professional installation guarantees the best results.

How Long Should I Wait Before Placing Furniture on New Concrete?

Most homeowners should wait at least 24-48 hours before placing light furniture on new concrete, but heavy items require a full 7-10 days for proper curing and maximum strength.

What Causes White Spots or Efflorescence on Concrete Patios?

Efflorescence occurs when water dissolves salt deposits within concrete and carries them to the surface. As moisture evaporates, these salts remain behind, creating white, chalky spots on concrete surfaces.

Can Plants or Tree Roots Damage My Concrete Patio Over Time?

Growing tree roots and aggressive plant systems can gradually crack and lift concrete patios by exerting pressure from below, causing structural damage and uneven surfaces over several years.

Is It Possible to Repair Cracks Without Replacing the Entire Patio?

Small to medium concrete cracks can be repaired using epoxy fillers, patching compounds, or concrete sealants. Many homeowners successfully fix these issues without needing complete patio replacement.

Expert Final Thougts

When choosing a concrete patio finish, homeowners must carefully weigh aesthetic preferences against practical considerations like maintenance needs, climate compatibility, and installation costs. While stamped concrete offers design versatility, acid staining provides rich color variations, and exposed aggregate delivers natural texture, each option presents distinct advantages and challenges. Through thoughtful evaluation of these factors, along with proper installation and maintenance, any of these finishes can provide decades of outdoor enjoyment and value.